Jahangir Shah, Dhaka: There were almost no factories in the country after independence. The industrial sector of Bangladesh started with only 313 factories in a war-torn country. According to official figures of that time, the country’s industrial sector incurred losses of Tk 2.9 million during the liberation war. In addition to the crisis over the company ownership, there was a shortage of loans and lack of skilled manpower. Despite that, this sector was recovering due to the various initiatives undertaken by the government at the time. These details were found while studying old official documents.

Fortunately, a huge entrepreneurial and business class has developed in that war-torn country over the last five decades. In addition to meeting the demand of the domestic market, the list of products for export has also grown.

The industrial sector has seen vast expansion in the last 50 years. The number of factories has multiplied 150 times. As a result, the number of factories in production has increased to 46,110. Of these, about 3,000 are large factories. These are now the mainstay of the country’s industrial sector.

The industrial sector has witnessed huge success in the last 50 years, as in evident in the fact that Bangladesh is now the world’s third largest exporter of ready-made garments. Bangladesh is also is a reputable exporter of leather products. And the golden days of jute and jute products are also being reinstated. At present Bangladesh ranks second in the world in terms of jute production. The country has also started manufacturing electronic products. Local companies are producing essential products like refrigerators, air conditioners and mobile phones.

Abul Kashem Khan, former president of Dhaka Chamber of Commerce and chairman of AK Khan Group, said, “The difference between from where we started and where we stand today is very clear. The government has supported entrepreneurs continuously through industrial policies. At the same time the entrepreneurs have also developed their competence. Therefore, we have succeeded to grow into the world’s third largest exporter of ready-made garments.”

He said, “It is high time that our entrepreneurs get the scope to work in the global arena.”

It wasn’t easy in the beginning

The first five-year plan of Bangladesh was finalised in November 1973 under the leadership of Nurul Islam, the then vice-chairman of the Planning Commission and an eminent economist. The plan details how much damage was done to the industrial sector during the war and how it then turned around.

At the end of the Pakistan period before independence, the number of registered industries in the country was 3,130 in 1968-69. Of them, 791 were companies from the apparel sector, the highest number of companies from a certain sector at the time. Besides, there were unregistered factories as well.

The fight to turn around

After the liberation war the country’s industrial sector faced multilateral crises. Massive changes came up in the ownership. As the Pakistani owners left their business establishments in Bangladesh after the country became independent, the state took the ownership of those factories.

In particular, jute, textile and sugar mills were nationalised. The nationalisation programme for the industries was announced on 26 March, 1972. This programme was taken to help the industrial sector turn around.

Sena Kalyan Sangstha and Muktijoddha Welfare Foundation were given the responsibility of running some of the factories. In total, the amount of property of the industry in the hands of the government at that time was Tk 5.17 billion.

As per the official figures of 30 June 1973, the country’s industrial sector started with 313 factories which was just the number of industries owned by the government. There were not many industrial establishments in the private sector then.

After that, various problems obstructing the development of the industrial sector were pointed out in the first five-year plan. It stated that as a result of nationalisation, a crisis of skilled manpower and managers in the jute and textile sectors had emerged. A dearth of economic analysts, accountants and marketing experts emerged as well as the managers. And then in the process of recovery, the labour discontent and the inability to motivate the workers in the industrial sector became a big issue.

Besides, industrial raw materials, intermediary products and consumer’s products were all imported from Pakistan. However, after independence the supply of these products couldn’t be restored. In addition, there was a power crisis. Due to the destruction of many roads and bridges during the war of liberation, the supply of goods was disrupted to a great extent immediately after independence.

Another big problem after independence was the challenge of providing loans to entrepreneurs. The first five-year plan said most entrepreneurs at the time needed capital to run a business. Many were unable to import raw materials due to lack of funds. Some ongoing development projects were cancelled then. The financial corporations of the country did not have a clear idea about their probable contribution up to that point.

The country’s industrial sector started its journey amidst this crisis. However, the industrial sector did not develop much in this country till the 90’s. Therefore, the contribution of the industrial sector to the country’s gross domestic product (GDP) still fluctuated between 10 to 20 per cent.

In the 90’s, the country adopted the free economy policy, providing the private entrepreneurs with various benefits.

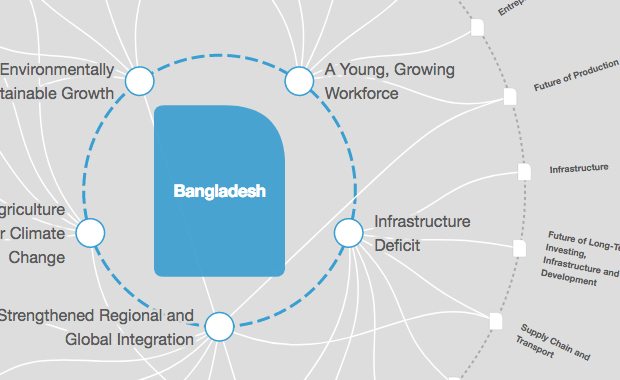

Zahid Hussain, former leading economist at the World Bank’s Dhaka office, thinks that mainly four factors have influenced the development of the industrial sector of the country. These are – trade benefits in the global sphere, availability of labour, interest of the entrepreneurs and government policy. Industrial revolution in a country usually starts with the apparel sector. And so was the case in many countries of the world.

The garment sector of the country embarked in the 1980’s with international trade benefits (quota benefit).There was also enough workers available in the country for the garment sector. Women who used to remain confined at home also came to work in the garments industry.

* This report appeared in the print and online edition of Prothom Alo and has been rewritten for the English edition by Ashish Basu